Wizard Tag

Wizard Tag reached a major milestone this month after receiving and testing the third (and possibly the final) revision of our Wizard Tag Wand circuit boards!

Designing electronic circuitry is not simple! Despite the expertise and experience of our Hardware and Printed Circuit Board Engineers, multiple revisions were necessary. We put all of the parts together, then tested them, added some components and changed others, then tested again. The third version is nearly perfect and will enable prototype testing!

How do you Perfect Circuitry?

Explaining the revision process for Printed Circuit Boards.

The process to design, evaluate, manufacture, and test circuit boards is not fast!

The electronics are called Printed Circuit Boards (PCBs) because the components are placed on the fiberglass boards by a giant automated printing machine that has reels of each type of electronic component that is needed by that board. PCB design is a specialized engineering field.

First, the hardware is selected that will accomplish the tasks required. Then, the PCB engineer places the components and creates the traces that connect them to the power supply. These include common components such as capacitors, resistors, LEDs and switches, and specialized parts like computer chips (processors), sensors, and accelerometers.

The design is checked with software to make sure that the circuits are good and that there is no interference with the case (pieces too close to the edge for example).

Then the boards are manufactured, which can include some manual work, such as soldering parts that the PCB machines cannot do. The work is checked at the factory and then delivered to the engineers for basic power and circuit testing.

Once the PCBs are released from the engineers, they go to Wizard Tag for testing. We load software to test all of the components and report back to the engineers for any necessary changes.

The first attempt was called Revision-Zero or Rev-0, the second was Rev-A, and the third set of PCBs was Rev-B.

What changes did we see in Revision-B?

- Infrared LEDs were rearranged to be staggered, so the long range LED won’t block the wide angle of the short range LED!

- More IR receiver sensors provide overlapping 360 coverage.

- Power to the IR systems is now wired directly to the power source.

- Custom battery contacts are stronger and more secure.

- The power pad was changed to a hidden tactile switch.

- New locator holes and notches help to align and secure the circuit boards in the case.

- Flashlight LED was changed.

- Resistor changes increased ranges for short and long range IR LEDs (the attack spells).

- Components were consolidated on the main board to simplify the PCB assembly.

- Memory was increased by 8x!

What remains for wand improvement?

Little remains to be changed in the hardware before production, due to the expertise of the engineers!

There will be a tiny change in the battery compartment to allow for slightly larger battery sizes. Other than that, most of the remaining work is in perfecting the case design and finalizing the software.

The case is progressing well, with prototypes in testing now. The software has many major areas completed, including menus, settings, motion control, and communication with Infrared and Bluetooth. Most of what remains to program involves the game modes.

So to sum it all up, Rev-B is a great success so far and will go a long way to helping us complete the Wizard Tag laser tag magic Wand!

Share your thoughts in the comments below!

- Are you interested in the technology behind the magic?

- What questions do you have about wand development?

Want more Wizard Tag updates?

Follow our Progress as we create Laser Tag for Wizards!

#makingmagicreal

Browse the Latest Blogs:

Game Review: The Vale of Eternity

- 6 min read

- Date: May 12, 2024

Game Night: Root

- 4 min read

- Date: May 5, 2024

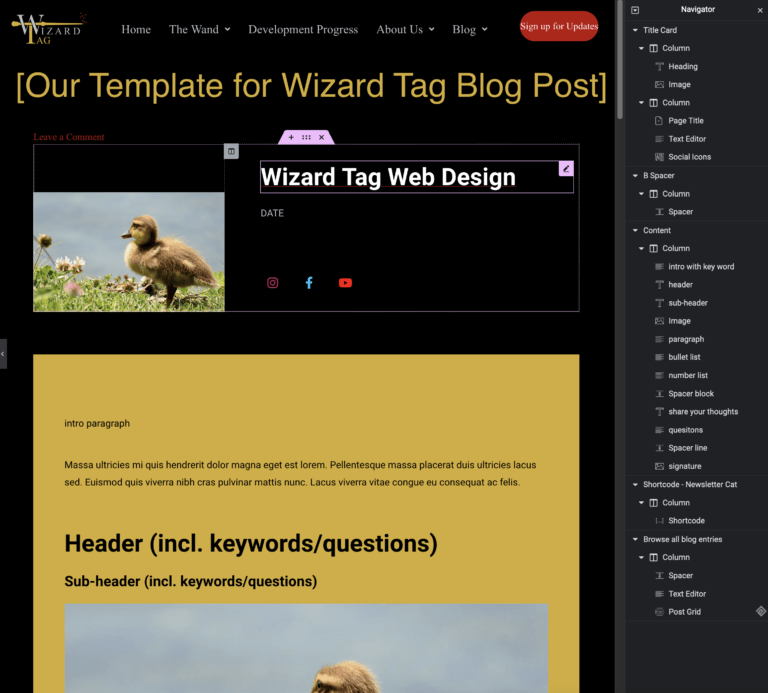

Wizard Tag Web Design

- 4 min read

- Date: April 28, 2024